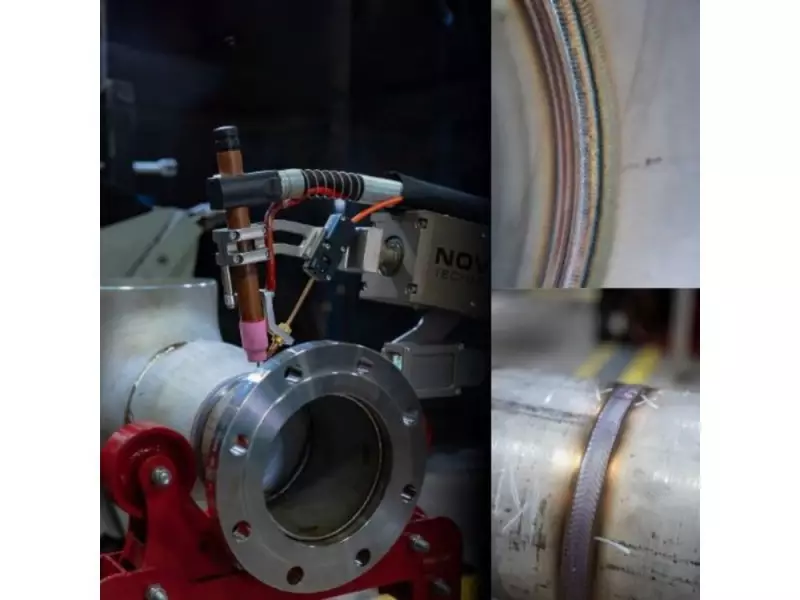

In a groundbreaking development for the manufacturing sector, Vancouver-based Novarc Technologies has unveiled what industry experts are calling the world's first fully autonomous TIG welding system. This revolutionary technology promises to transform industrial fabrication by combining advanced robotics with sophisticated artificial intelligence.

Revolutionizing Precision Welding

The Spool Welder 1000 represents a quantum leap in welding technology, specifically designed for high-precision TIG (Tungsten Inert Gas) applications. Unlike traditional automated systems that require extensive programming and manual intervention, this innovative solution operates completely autonomously, making real-time adjustments based on visual feedback and environmental conditions.

Addressing Critical Industry Challenges

The autonomous welding system arrives at a crucial time for the manufacturing industry, which faces significant challenges including:

- Severe shortages of skilled TIG welders across North America

- Inconsistencies in weld quality and productivity

- High labor costs and training requirements

- Safety concerns in hazardous welding environments

Novarc's solution directly addresses these pain points by delivering consistent, high-quality welds without human intervention.

Unprecedented Performance Metrics

Early adopters and beta testers report remarkable results, with the autonomous system demonstrating:

- 400% increase in productivity compared to manual welding

- Consistent, flawless weld quality across thousands of cycles

- Significant reduction in material waste and rework

- 24/7 operation capability without fatigue or breaks

British Columbia's Growing Tech Ecosystem

This innovation underscores British Columbia's emergence as a global hub for advanced manufacturing technology. Novarc's success follows a pattern of Canadian technological leadership in industrial automation, building on the region's strengths in engineering talent and innovation culture.

The company's achievement is particularly notable given the complex challenges of TIG welding, which requires extreme precision and consistency that has traditionally demanded highly skilled human operators.

Future Implications for Manufacturing

Industry analysts predict that Novarc's breakthrough will accelerate the adoption of autonomous systems across multiple sectors, including:

- Aerospace and defense manufacturing

- Pharmaceutical and food processing equipment

- Semiconductor fabrication facilities

- Renewable energy infrastructure

The technology represents not just an incremental improvement, but a fundamental shift in how precision fabrication will be approached in the coming decades.

As manufacturing continues its digital transformation, innovations like Novarc's autonomous welding system position Canadian technology firms at the forefront of the Industry 4.0 revolution, creating new opportunities for economic growth and technological leadership on the global stage.