Researchers at the University of British Columbia have unveiled a groundbreaking method that could dramatically clean up the production of rayon, a popular but chemically-intensive fabric. The innovation promises to reduce the use of toxic solvents by as much as 70%, offering a more sustainable future for the textile industry.

A Cleaner Spin on a Classic Fabric

For decades, rayon has been prized for its soft, cotton-like feel. However, its manufacturing has relied heavily on harsh chemicals, particularly carbon disulphide. Associate professor Feng Jiang from UBC's faculty of forestry explains that this substance is toxic, posing serious risks to nervous and cardiovascular systems and is a known carcinogen. Traditionally, the solvents used are discarded after production, creating significant environmental waste.

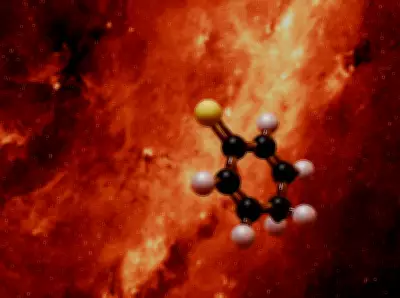

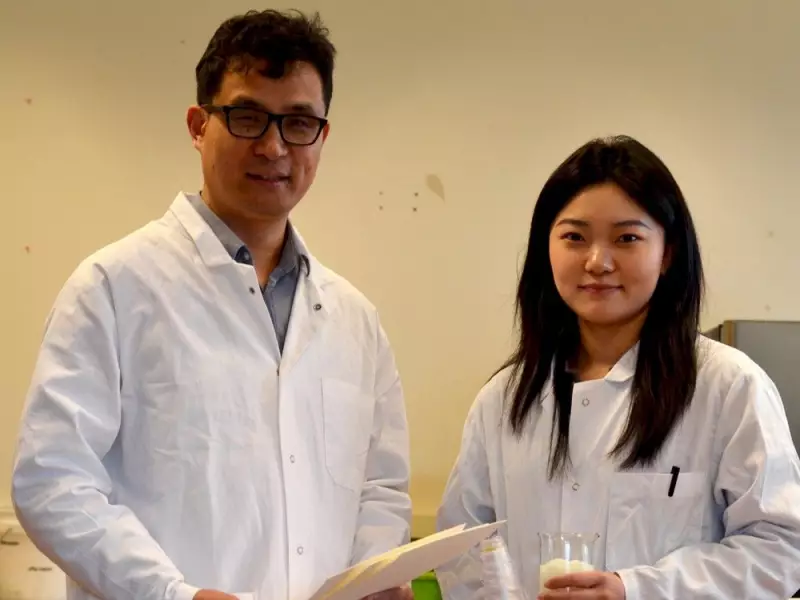

The new technique, developed by Jiang and doctoral student Huayu Liu, pivots away from dissolving all the wood pulp. Instead, it incorporates microfibrillated cellulose—thin strands created by mechanically grinding down wood pulp. This material is then spun at room temperature using a non-dissolving solvent.

The peer-reviewed study, published in the journal Chem Circularity in December 2025, details how this approach can cut solvent use by up to 70 per cent. This not only slashes the chemical footprint but also reduces energy consumption and associated costs.

Closing the Loop on Textile Production

Professor Jiang emphasizes that their method represents a shift toward a circular, or closed-loop, processing model. "All the ingredients or the chemicals we are using can be recycled and reused," he stated. This stands in stark contrast to the conventional linear process where chemicals are used once and thrown away.

The resulting fibre maintains the desirable qualities of traditional rayon: it is soft, has a natural texture akin to silk or cotton, and remains fully biodegradable. "It's just like paper and will eventually break down in the environment," Jiang confirmed, highlighting that the environmental benefit comes without sacrificing performance.

Furthermore, the source material is flexible. While the initial research uses wood pulp, Jiang notes the strands could also be derived from other sustainable sources like hemp or grass, opening doors for agricultural byproducts to enter the fashion supply chain.

Next Steps for B.C.'s Green Economy

The UBC team has ambitious plans to scale their discovery. Future steps include collaborating with Kwantlen Polytechnic University for testing and prototyping. They also aim to explore alternative fibre sources in more depth.

Jiang sees significant potential for local economic benefit. "I think this would be very good for the local economy," he said, expressing a goal to eventually create fabric using fibres sourced from within British Columbia. This innovation positions rayon to become a truly sustainable choice for clothing, diapers, and other textiles, aligning the needs of the fashion industry with urgent environmental imperatives.

The research addresses a critical need in the textile sector for alternatives to petroleum-based fibres like polyester. By offering a cleaner path for a beloved material, UBC's work paves the way for a less toxic and more sustainable wardrobe future.