First Atlantic Nickel Corp. has announced breakthrough metallurgical results from its ongoing drilling campaign at the Pipestone XL Nickel Alloy Project in central Newfoundland. The company reported that drill hole AN-25-10 has delivered the highest magnetically recoverable nickel grades and recovery rates achieved to date at the project's RPM Zone.

Record-Breaking Drill Results

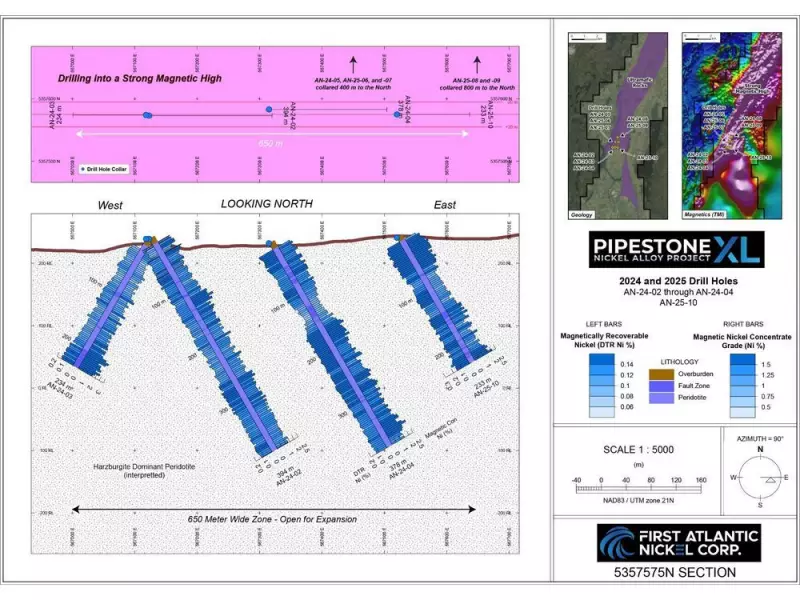

The latest results from the Phase 2X expansion drilling are drawing significant attention. Hole AN-25-10 averaged 0.15% Davis Tube Recovery (DTR) nickel over a substantial 228-meter interval. This result was calculated from a magnetic concentrate grading 1.44% nickel with a mass pull of 10.48%, indicating that magnetic separation can reduce the starting rock volume by approximately 90%.

This performance represents a 25% increase over the RPM Zone's previous average of 0.12% DTR nickel. The hole also achieved an impressive 68.62% magnetic nickel recovery from a whole-rock assay grade averaging 0.22% nickel over the entire hole.

High-Grade Intervals and Expansion Potential

The drill hole intersected exceptional high-grade intervals, including 0.17% DTR nickel from 8 to 59 meters (a 51-meter section) and 0.16% DTR nickel from 215 to 236 meters (a 21-meter section). Notably, the drilling stopped in mineralization at 233 meters after encountering a clay-filled fault zone, suggesting the resource remains open at depth.

Strategically, hole AN-25-10 is positioned 200 meters east of the company's previous best result from hole AN-24-04, which reported 0.14% DTR nickel over 366 meters. This confirms that the eastward expansion drilling toward an area known as Chrome Pond continues to yield above-average results.

The Awaruite Advantage for Battery Supply Chains

A key differentiator for the Pipestone XL project is the mineralogy of the nickel resource. The nickel is hosted in awaruite (Ni₃Fe), a naturally occurring nickel-iron-cobalt alloy that already exists in a metallic state containing approximately 77% nickel.

This contrasts sharply with conventional nickel sulfide minerals like pentlandite, which contain sulfur and require energy-intensive smelting or roasting for removal. Awaruite's metallic composition offers a potential mine-direct-to-refinery pathway, bypassing the bottleneck of limited North American smelting capacity. This could be pivotal for developing large-scale domestic nickel production for electric vehicle battery supply chains.

Chromium Byproduct and Future Plans

In addition to nickel and cobalt, the RPM Zone drill holes consistently show disseminated chromium. The company has expanded its metallurgical program to include chromium as a potential byproduct. Chromium values in hole AN-25-10 averaged 1.54% in the magnetic concentrate, with mineralogy studies identifying chromite as the chromium-bearing mineral.

First Atlantic Nickel plans to announce additional drilling around hole AN-25-10, with optimized drilling designed to penetrate deeper and continue the eastward expansion toward Chrome Pond. Historic sampling in that area has returned values of up to 62.2% Cr₂O₃, making it a high-priority target.

The company's ongoing metallurgical program, which includes mineralogy, recovery, and concentrate testing, is now also evaluating the potential for a high-grade chromium concentrate. Updates on recovery, separation, and preliminary concentrate products for nickel, chromium, and cobalt are anticipated in early 2026.