PyroGenesis Confirms Commercial Grade 150 Fumed Silica Through Independent Verification

Montreal-based PyroGenesis Inc., a leader in ultra-high temperature processes and plasma-based technology, has achieved a significant milestone in its fumed silica production. The company has received additional independent verification confirming that its fumed silica meets established commercial grade 150 standards, marking a crucial step toward industrial-scale applications.

Independent Verification Confirms Commercial Viability

Following recent test results from the company's fumed silica reactor (FSR), PyroGenesis has obtained confirmation from multiple independent laboratories that the material produced during Test #7 meets commercial benchmarks. The verification specifically confirms that the fumed silica achieves a specific surface area of approximately 150 m²/g under BET analysis while simultaneously meeting required viscosity standards for commercial grade 150.

"The results of test 7, and subsequent analysis and verification by two unrelated independent entities, confirm that the fumed silica reactor is now producing fumed silica at the important 150 commercial product grade," stated P. Peter Pascali, President and CEO of PyroGenesis. "As important is the fact that we have now replicated, at pilot scale, the results from our original lab-scale results for both viscosity and surface area of fumed silica."

Scaling Production for Industrial Applications

The achievement represents a breakthrough in scaling production from laboratory to pilot plant levels. According to company leadership, the viscosity results are particularly noteworthy as they indicate that fumed silica produced at the pilot plant can be suitable for various industrial applications including:

- Coatings and adhesives

- Sealants and inks

- Elastomers and insulation binders

Viscosity, often referred to as rheology efficiency, serves as a critical performance metric in these applications. The successful scaling addresses what had been a persistent question about whether laboratory results could be effectively reproduced at larger production scales.

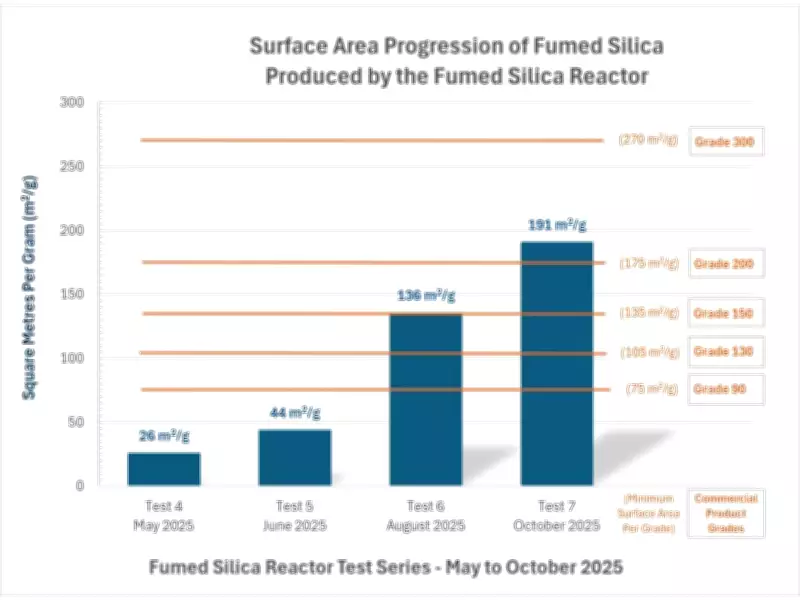

Progressive Improvement in Surface Area

Over recent months, PyroGenesis has implemented ongoing system modifications to its fumed silica reactor, resulting in progressive improvements in surface area measurements. The company has increased surface area from an initial recorded result of 26 m²/g to the current 191 m²/g, demonstrating consistent technological advancement.

Commercial fumed silica products are typically sold at various surface area measurements including:

- 90 m²/g

- 130 m²/g

- 150 m²/g

- 200 m²/g

- 300 m²/g

The company plans to continue improving surface area measurements as it targets additional commercial applications beyond the current grade 150 achievement.

Industry Context and Market Applications

Fumed silica represents one of the most widely used industrial materials globally, appearing in thousands of products across multiple sectors. Common applications include:

- Cosmetics and personal care products

- Food and pharmaceutical applications

- Construction materials and industrial coatings

- Batteries and electronics

- Automotive components including tires

The material typically functions as a thickening and anti-caking agent, helping to stabilize and improve texture, consistency, and flow characteristics in end products. In specialized applications, fumed silica is often combined with other materials to enhance performance characteristics. For instance, in tire manufacturing, it blends with carbon-black to improve wear and efficiency, while in battery production, it combines with graphite to enhance slurry uniformity and conductivity.

Strategic Partnerships and Commercialization

PyroGenesis has been engaged to develop and build the FSR pilot plant for HPQ Polvere Inc., a subsidiary of HPQ Silicon Inc. The company maintains a 50% interest in Polvere and holds an exclusive arrangement to serve as the sole supplier of equipment relating to any commercialization of this new fumed silica production process.

The independent verification of commercial grade 150 standards represents a significant validation of PyroGenesis's technological approach and positions the company for potential expansion into broader industrial markets where fumed silica serves as a critical component material.