Montreal-based engineering firm PyroGenesis Inc. has secured a significant contract valued at over $1.3 million to advance the electrification of a key process in cement manufacturing, marking a pivotal step in the heavy industry's energy transition.

A Strategic Contract for Cleaner Cement

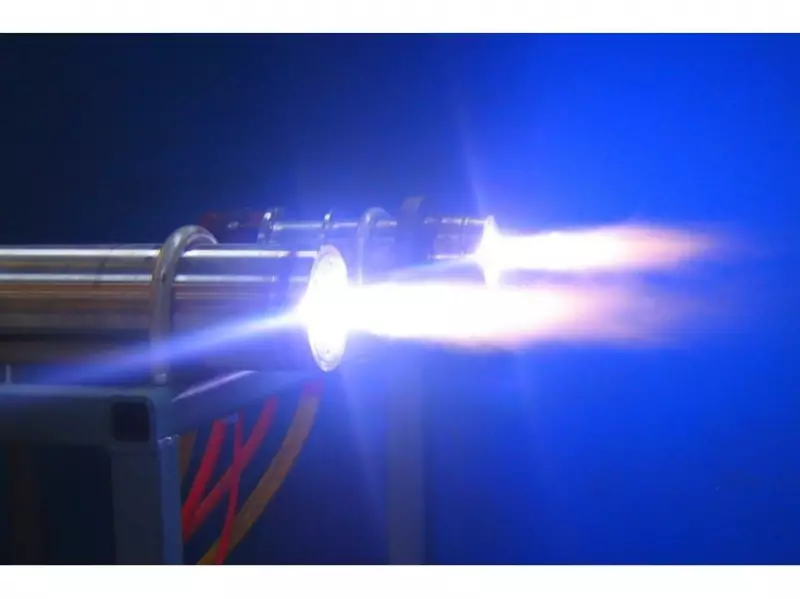

The company announced on December 3, 2025, that it signed a deal worth €815,000 (approximately CAD$1,324,000) with a major European player in the cement and minerals sector. The contract is for the supply of PyroGenesis's proprietary plasma torch system, which will be integrated into a calcination furnace. The identity of the client remains confidential for competitive reasons.

This project, initially hinted at in the company's Q2 financial outlook in August 2025, involves using an electric plasma torch as a heating source to replace traditional fossil fuel combustion. The core objective is to demonstrate a cleaner, more efficient method for the high-temperature calcination process, which is essential for producing cement clinker, lime, and soda ash.

Innovating with Closed-Loop CO2

A particularly innovative aspect of the project is the planned use of a CO2-powered plasma torch. The carbon dioxide will not be newly emitted; instead, it will be captured from other industrial processes and fed into a closed-loop system to power the torch that heats the furnace. This approach tackles emissions from two angles: eliminating fossil fuel burners and utilizing captured CO2.

The delivery of the plasma system is targeted for early in the third quarter of 2026. Following delivery, the client will conduct a nine-month test as part of a broader, multi-year initiative. The ultimate goal is to prove that electric heating can permanently replace fossil fuels in cement kilns on an industrial scale, moving from previous low-power tests to megawatt-level applications.

Targeting a Major Source of Industrial Emissions

The cement industry is one of the world's largest industrial sources of greenhouse gases. A substantial portion—approximately 40%—of its emissions comes from burning fuel to generate the extreme heat required for calcination. By replacing traditional burners with plasma torches, the industry can make a direct and profound cut to its carbon footprint.

"The cement industry is under mounting pressure to shift toward cleaner technology for their high temperature process steps," said P. Peter Pascali, President and CEO of PyroGenesis. He emphasized that adopting plasma technology is not only about operational efficiency but is vital for achieving the sector's net-zero emission goals. "Replacing fossil fuel burners with plasma torches offers a powerful pathway to deep decarbonization," Pascali stated, expressing encouragement at the growing momentum for plasma adoption in this targeted industry.

This contract underscores the increasing push within hard-to-abate sectors like cement to find innovative technological solutions for decarbonization, positioning Canadian cleantech firms like PyroGenesis at the forefront of this global energy transition.