HPQ Silicon's Fumed Silica Pilot Reactor Achieves Commercial Grade Verification

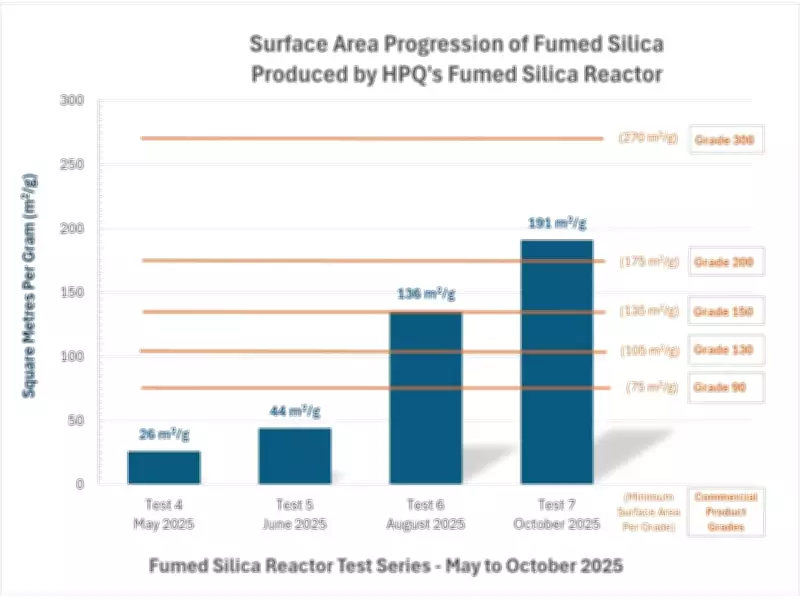

MONTREAL – HPQ Silicon Inc., a technology company specializing in advanced materials and critical process development, has reached a significant commercial milestone. The company has received independent verification from a potential customer that fumed silica produced by its pilot-scale reactor meets or exceeds commercial product grade "150" specifications.

Independent Confirmation of Commercial Specifications

The verification confirms that material produced during Test #7 achieves established commercial benchmarks for fumed silica. Specifically, the material demonstrates a specific surface area of approximately 150 m²/g under BET analysis while simultaneously meeting required viscosity standards for commercial grade 150 products.

This achievement represents a crucial step forward, as the pilot plant has now fully replicated results previously obtained through HPQ Silica Polvere Inc.'s original lab-scale tests. Those initial tests, verified by McGill University, first indicated the potential for producing commercial-grade fumed silica from quartz using a plasma-based system.

Technical Significance of Viscosity Achievement

In commercial applications including coatings, adhesives, sealants, inks, elastomers, and insulation binders, viscosity represents a critical performance metric for fumed silica. Often referred to as rheology efficiency, viscosity governs thickening capabilities, suspension stability, and application behavior in various industrial formulations.

The pilot-scale reactor has demonstrated particularly promising results in this area. Test data indicates that viscosity achieved by the fumed silica reactor exceeds typical commercial grade 150 benchmarks by approximately 10 percent. This technical achievement holds substantial significance because viscosity reflects the combined influence of surface area, aggregate structure, and surface chemistry under formulation conditions.

Commercial Implications and Market Expansion

Exceeding grade 150 performance by a double-digit percentage indicates a well-developed three-dimensional network and strong thickening efficiency. These characteristics prove essential for stability in high-performance formulations across multiple industrial sectors.

The company believes this announcement further validates the potential commercial performance of its proprietary plasma-based process for producing hydrophilic fumed silica directly from quartz. This innovative approach operates without chemical inputs and generates no hazardous by-products during production.

With both surface area results surpassing commercial product grade 150 minimums and viscosity thresholds now independently verified, the fumed silica reactor demonstrates its ability to reproduce laboratory-level benchmark performance at pilot scale. This development suggests that material produced at the pilot plant could prove suitable for various industrial applications, potentially expanding the target market for reactor-produced fumed silica into new commercial sectors.

The verification represents a significant step toward commercial viability for HPQ Silicon's innovative production technology, potentially positioning the company as a competitive player in the advanced materials market.