As crews work to restore the critical Bearspaw South feeder main, a central debate has emerged: should the City of Calgary rely on traditional steel or consider modern alternatives like high-density polyethylene (HDPE) for the repairs? The city has made its choice, firmly backing steel for this essential piece of infrastructure.

City Officials Advocate for Steel's Strength and Longevity

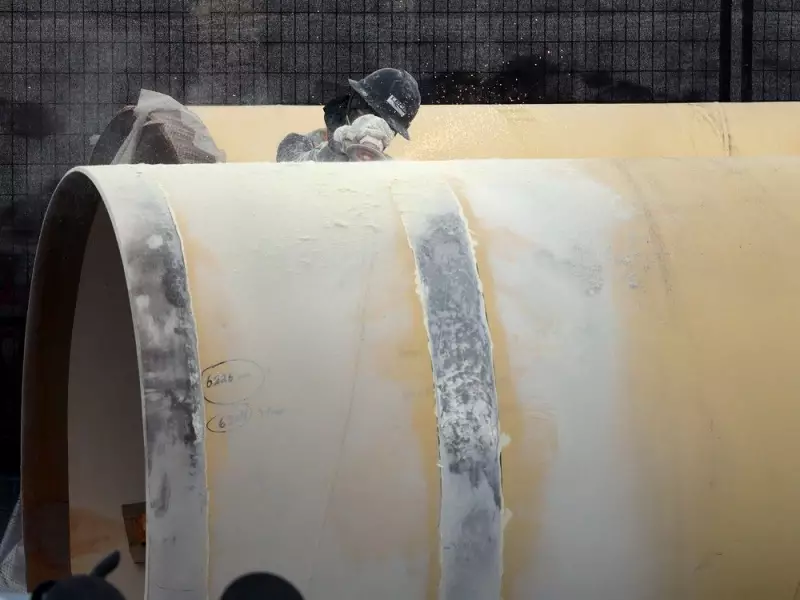

In a statement provided in January 2026, City of Calgary communications strategist Anna Blaxley outlined the reasoning behind selecting steel pipe for the Bearspaw South Feeder Main Improvements Project. The project involves adding new steel pipe of the same size to the existing main.

"This steel pipe will replace the concrete sections of the feeder main which improves and protects Calgary’s treated water distribution system," Blaxley said. The decision followed a detailed, project-specific engineering and risk assessment.

Blaxley emphasized that for a large-diameter, high-pressure transmission main like the Bearspaw line, steel is the preferred material. The choice was based on practical needs for installation, future maintenance, efficiency, pressure durability, and overall longevity. The use of steel allows for controlled installation, field welding, and rigorous inspections during construction, giving the city confidence in the pipe's ability to move water safely and reliably.

"Steel pipe performs reliably under high operating pressures and pressure changes," she added, noting the pipe will be protected with modern coatings and cathodic protection systems to prevent corrosion. "For critical infrastructure like the Bearspaw South feeder main, steel is a safe, reliable option."

The Case for High-Density Polyethylene (HDPE)

Not all industry voices agree with the city's direction. Kimberly Benson, founder and president of Pinnacle Pipe and Fusion, advocates for the use of HDPE over materials like steel or PVC. As an HDPE distributor, her company highlights several potential advantages of the plastic alternative.

Benson points to lower material, installation, and lifecycle costs as key benefits. HDPE pipe is significantly lighter than steel, which can allow for faster installation with fewer crews and less heavy equipment. From an environmental perspective, she notes HDPE has a lower carbon footprint and is fully recyclable.

Regarding steel, Benson raises concerns about corrosion and additional costs. "Steel is known to corrode, and if it’s not going to corrode, it’s because you have it epoxy coated or some sort of lining on it that helps it not corrode but then you’re just adding an extra layer of cost," she explained. She also mentioned that steel is subject to international tariffs, which can impact market conditions and pricing.

A Decision with Lasting Implications for Calgary

The choice of material for repairing the Bearspaw South feeder main is not merely a technical specification; it is a long-term investment in Calgary's water security. The city's position, backed by its engineering assessment, prioritizes proven performance under extreme pressure and a legacy of use in critical transmission mains.

While alternative materials like HDPE present compelling arguments regarding cost, speed, and environmental impact, the city's strategy errs on the side of traditional strength and a maintenance philosophy built around steel. This decision will shape the reliability and maintenance needs of this crucial water artery for decades to come, as work continues to bring the feeder main fully back online.